Patented Self-Lubricating Liner Technologies

High-performance fabric-based and machineable composite solutions provide optimal performance in a wide range of operating conditions.

Advanced Self-Lubricating Liner Solutions

NHBB is a leader in the development of self-lubricating liner solutions for demanding aerospace applications, such as engine mounts, landing gear gland assemblies, helicopter pitch-link control systems, and more. The many woven PTFE fabrics and machineable compounds we've developed contain specific properties that address any number of operating conditions and performance objectives. Wide-ranging solutions provide improved wear resistance for increased bearing life, machineability for precise fit and function, superior corrosion and moisture resistance for consistent performance in harsh conditions, high-temperature resistance for durable performance in the hot zone of jet engines, and more.

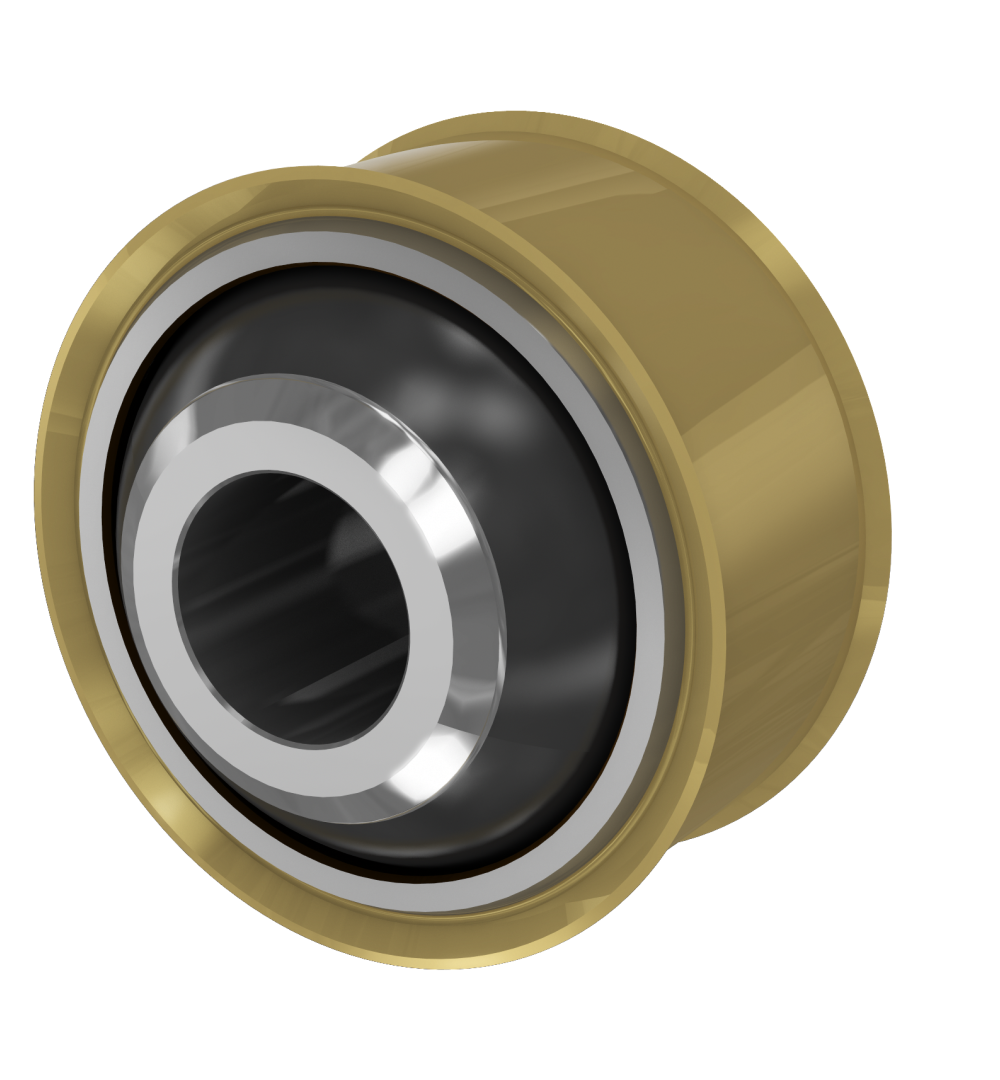

INVINSYS®

An innovative pitch control bearing technology that lasts up to two and a half times longer than previous designs helps reduce maintenance and repair costs of helicopter pitch control systems.

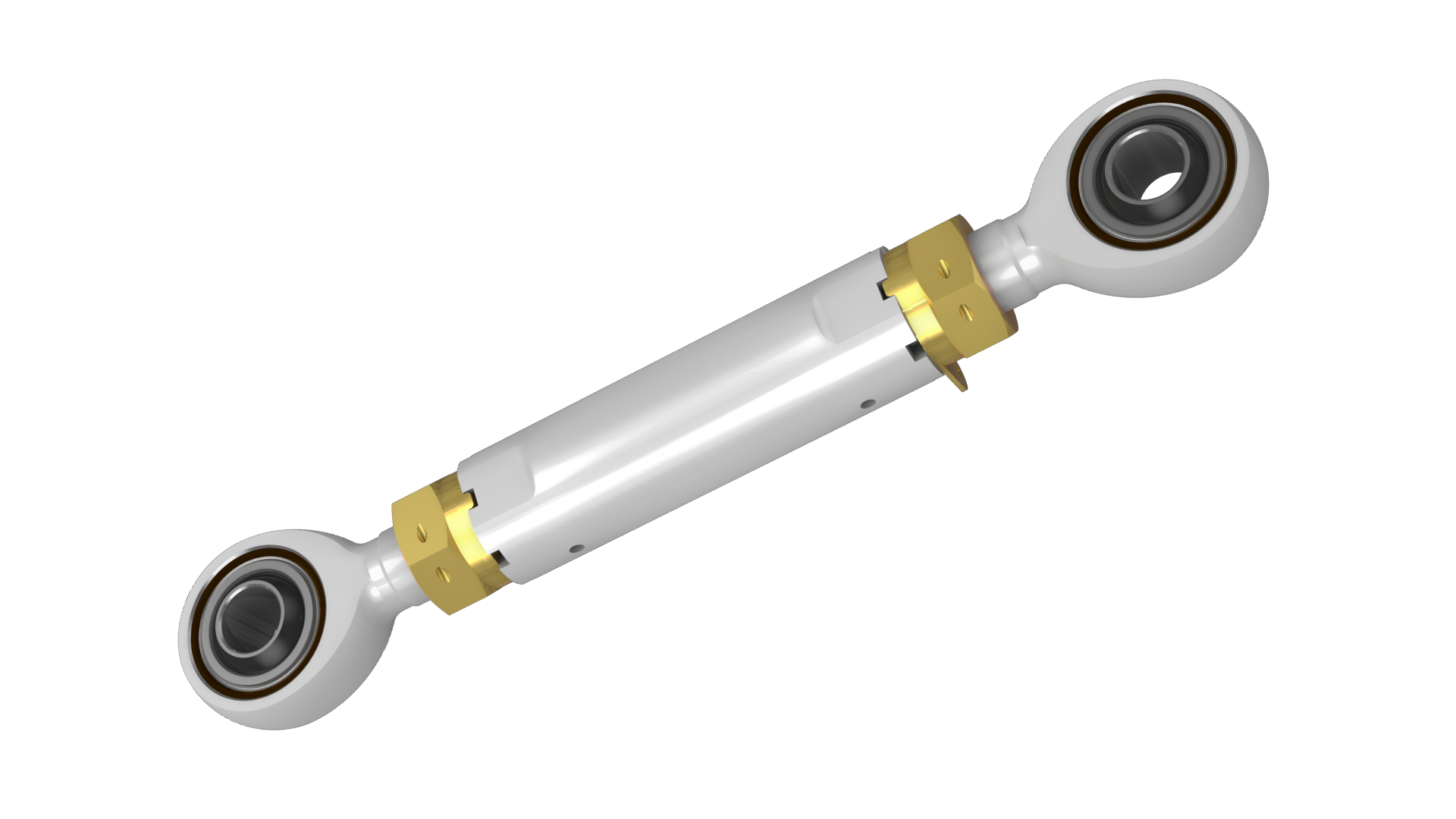

Oscimax® and Minelon®

NHBB and MinebeaMitsumi's machinable liner technologies offer exceptional wear life and consistent, reliable performance while achieving tighter tolerances. Available solutions range from cost-effective standard bearings to high-value custom components as well as line-only applications on customer parts.

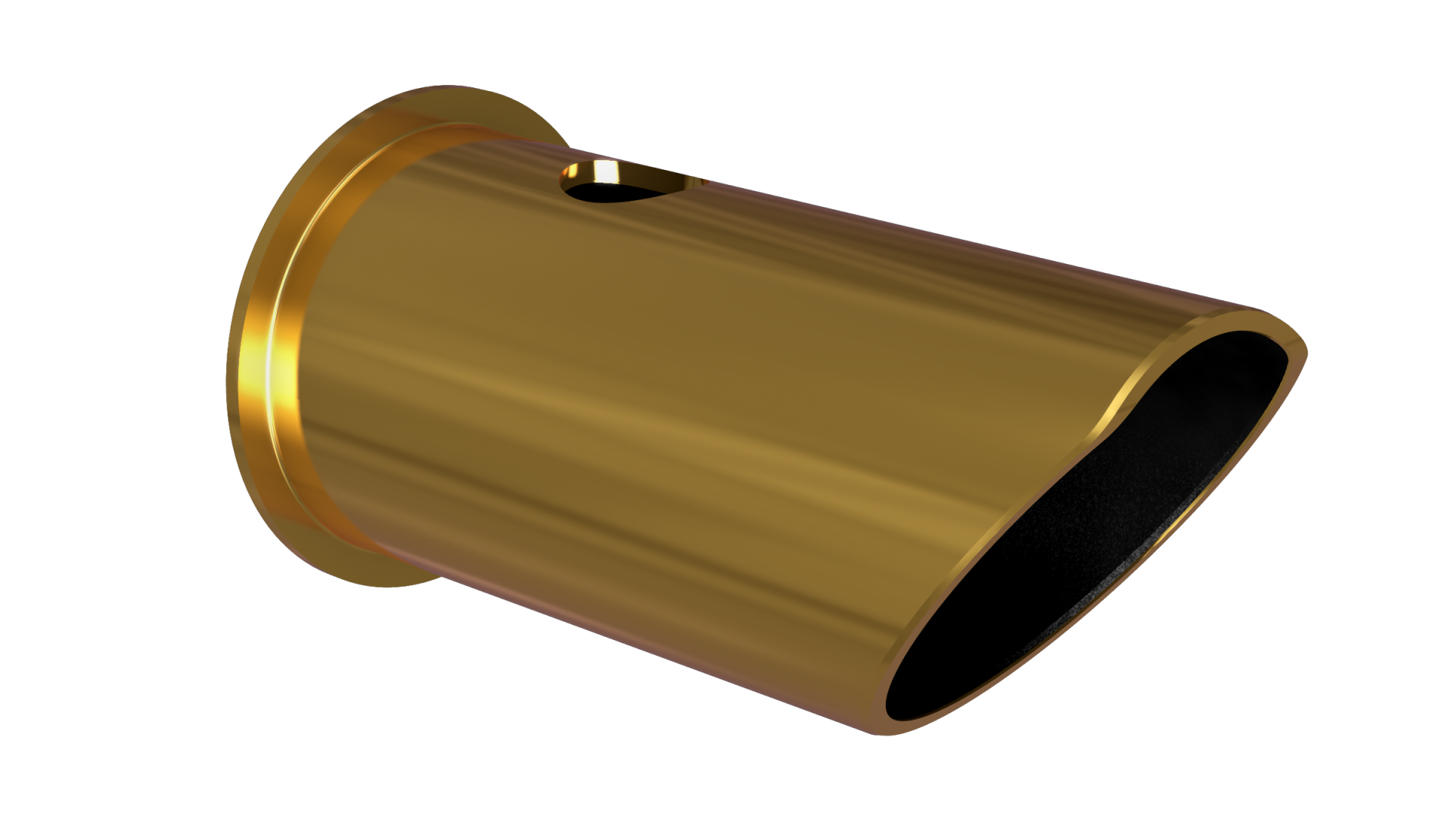

VULKYN®

A high-temperature self-lubricating liner solution with a maximum operating temperature of 75°F higher than previous designs. Vulkyn® is ideal for both military and commercial aero-engine applications in which bearings are exposed to sustained operating temperatures above 350°F.

Resource library

Quick access to useful documents, catalogs and other technical assistance material to help you find what you are looking for.