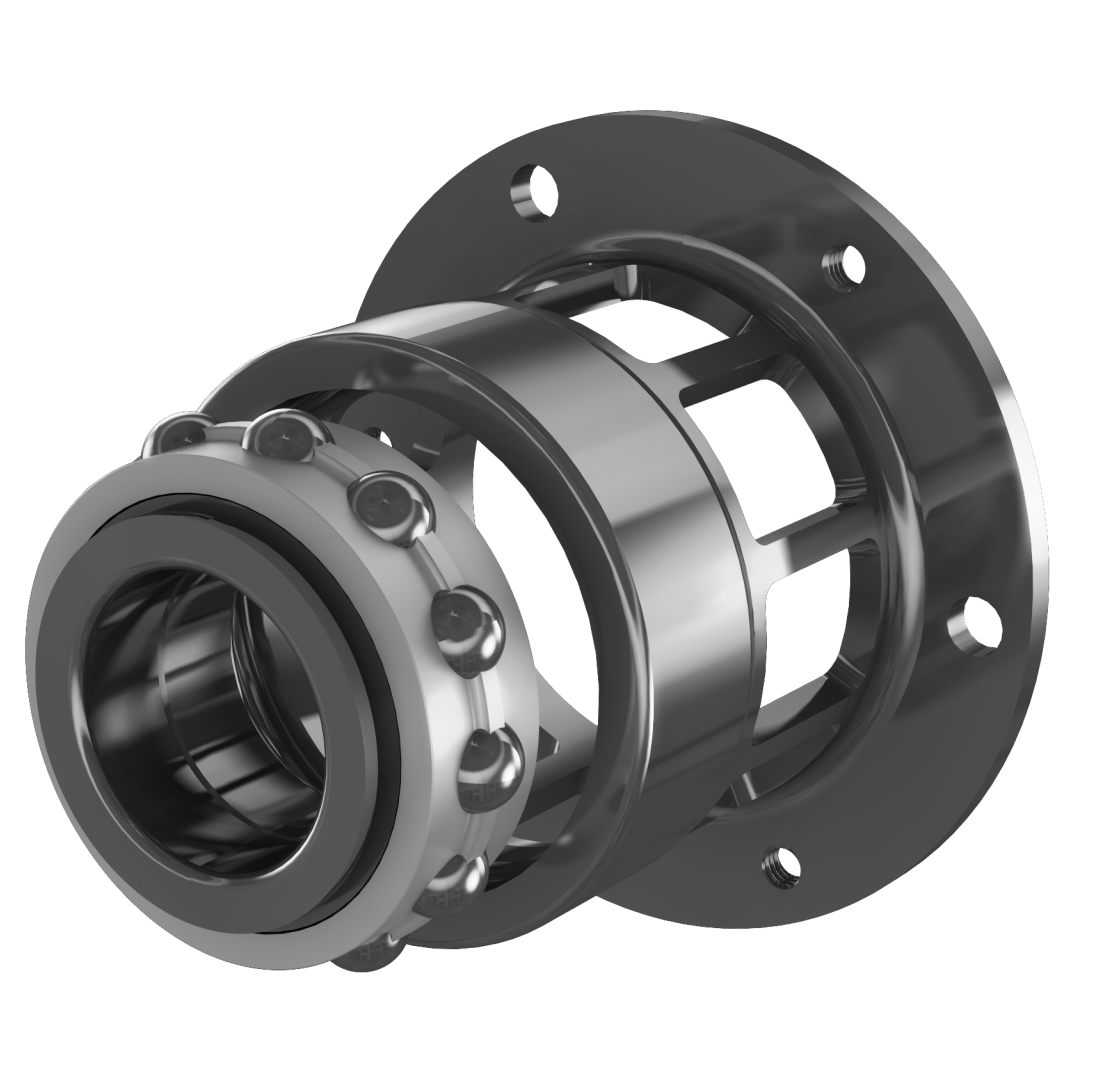

Complex Bearing Assemblies

Custom engineered solutions designed to satisfy a wide range of mechanical requirements.

Design Basics

Complex ball and roller bearing assemblies we manufacture are custom designed for small to large high-performance mechanical systems, such as aero-engine main shafts, APU’s, and helicopter transmissions. These highly engineered solutions meet demanding bearing performance criteria and fulfill a wide range of additional mechanical requirements, such as reduced vibration and noise, optimized lubricant distribution and scavenging, ease of installation/disassembly, and precise bearing positioning. Bearing engineering, prototyping, and testing are accomplished through a collaborative process between our experienced applications engineers and our customer’s product design and engineering teams. The result is a sophisticated bearing that exactly meets the customer’s needs.

Design Options

- Diverse ball and roller ring configurations

- Specialized corrosion- and heat-resistant ring materials

- Advanced alloys suitable for case-hardening

- High-grade steel and ceramic rolling elements

- Rugged cages made from high-temperature alloys & thermoplastics

- Integrated features for optimized form, fit and function

Resource Library

Quick access to useful documents, catalogs, and other technical assistance material to help you find what you are looking for.