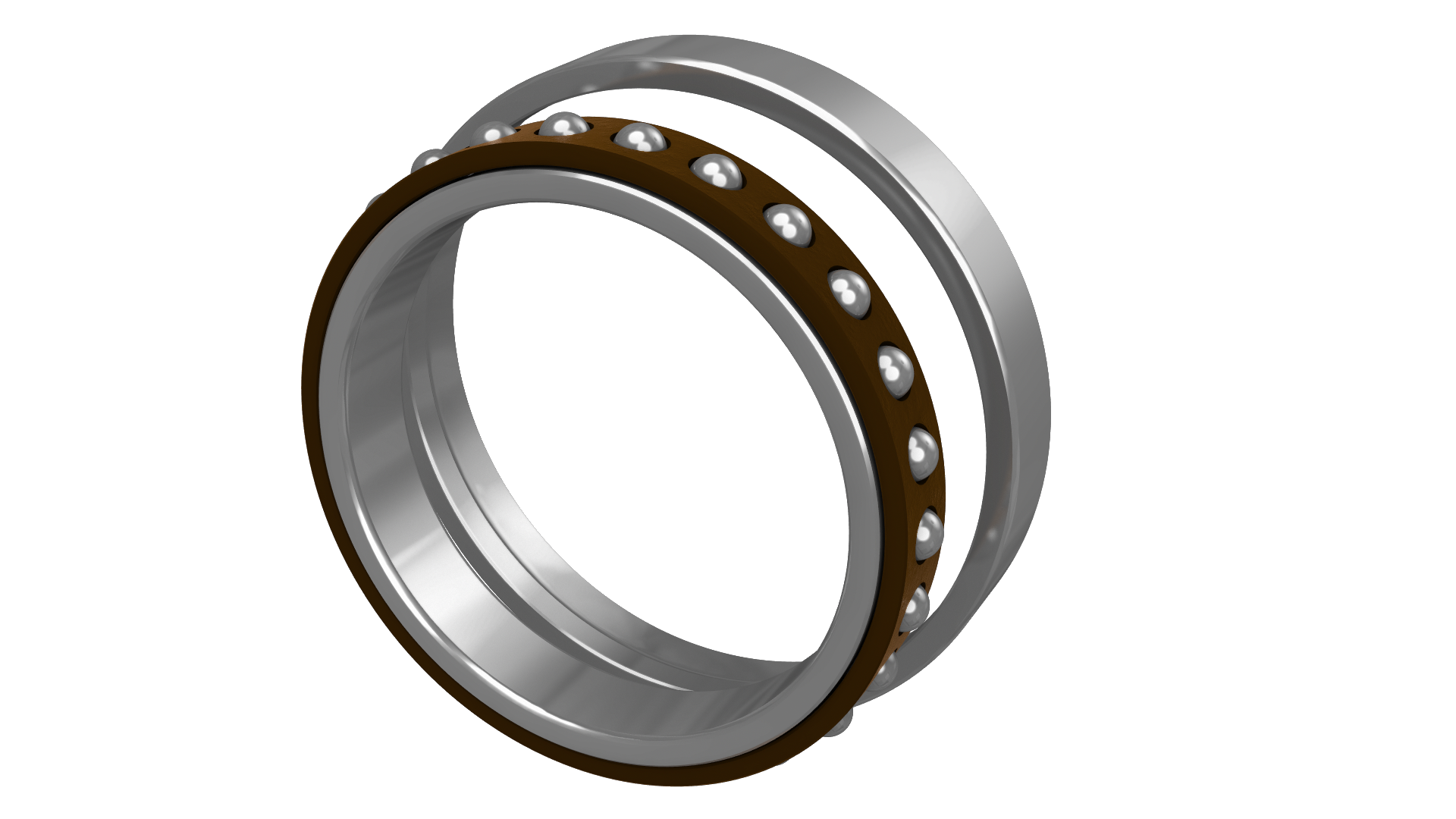

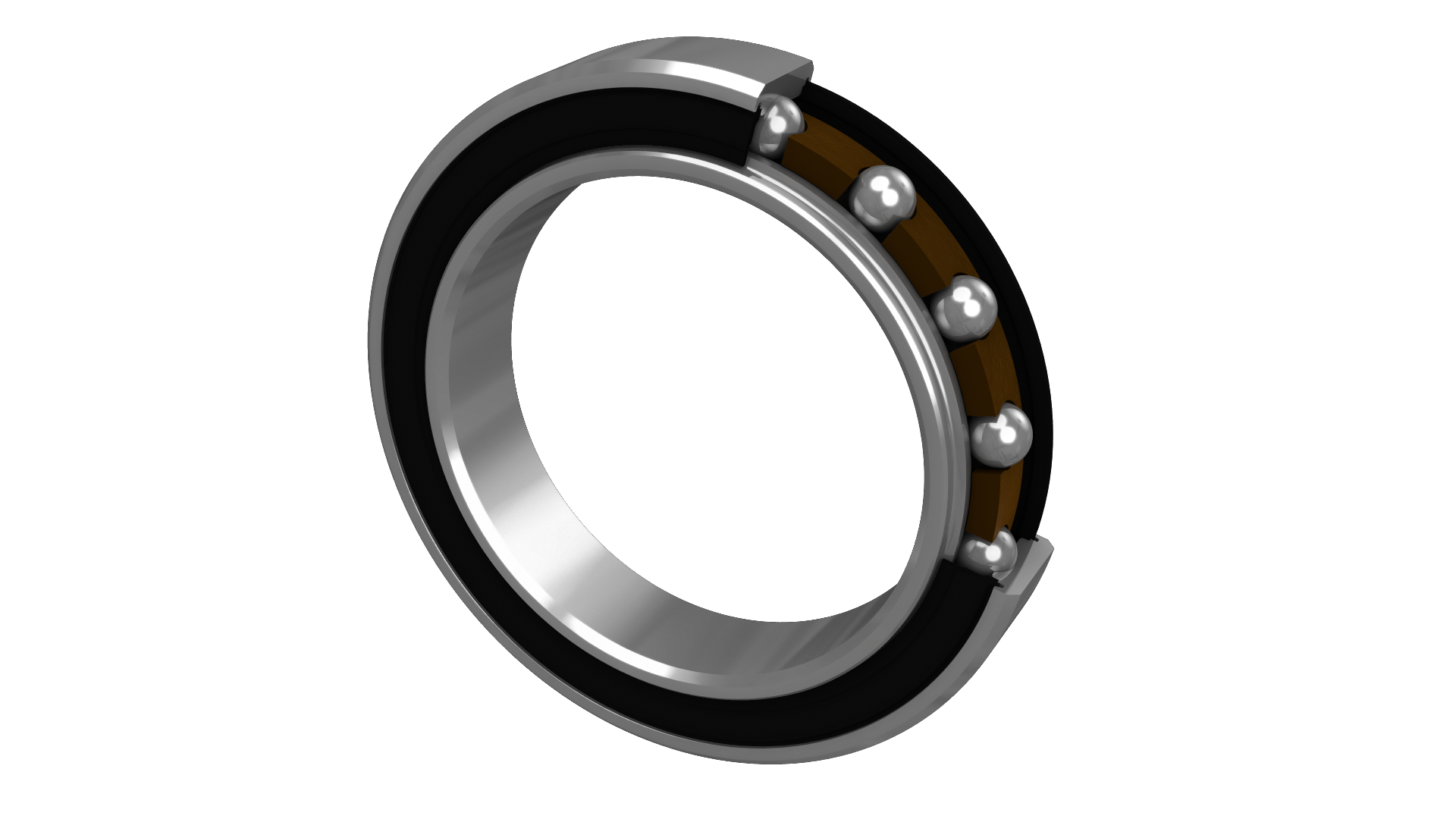

Thin Section Ball Bearings

Space-saving and light weight solutions engineered for precise fit, smooth rotation, and reliability.

Design Basics

Thin section and torque tube ball bearings are designed for applications with space and weight constraints and relatively light load requirements, and when high accuracy, high stiffness (less deflection), and low friction are required. Our family of inch series radial, angular contact, and gothic arch thin section bearings are available in bore sizes up to 3.065 inches (77.788mm) for torque tube and 10.00 inches (254mm) for thin section designs. Standard bearing options include extended inner rings and shields or seals. We also provide many component options to enhance the performance and operating life of thin section bearings.

Design Options

- High precision tolerances

- Premium selection of corrosion- and heat-resistant ring materials, such as BG42 and CREN

- High-grade steel/ceramic balls and special ball coatings

- Molded & machined cages made of high temp. alloys and thermoplastics

- Specially formulated synthetic oil, grease and dry film lubricants

- Integrated features for optimized form, fit and function, including extended inner rings

Bearing Series & Types

Thinex (M&I)

Thin Section (Medium to Large)

Torque Tube (M&I)

Torque Tube (Medium)

Resource Library

Quick access to useful documents, catalogs, and other technical assistance material to help you find what you are looking for.

Bearing Customization and New Product Development

In addition to providing you with standard products, we can customize bearings to work outside the usual spectrum of load, temperature, corrosion resistance, and rotational speed. If you are designing a new aircraft subsystem, our product engineers can assist you with bearing selection, design, and engineering.

For heightened performance challenges, our applications engineering department may involve the New Product Development Center to identify and develop a unique solution.