Engineering Reference

Rod End & Spherical Bearings

Dry Film Lubrication

Dry film lubrication is suitable alternative to grease in select applications due to its unique properties and performance characteristics. Dry film is especially beneficial in applications featuring uni-directional loading, which tends to squeeze grease from the bearing area. This one factor alone is not sufficient to determine whether a dry film is preferred, so a range of other details must be considered, including bearing envelope requirements, materials, relative movement, and allowable wear, to name a few. Included below is a brief description of dry film lubricants as well as a table of the most common products used with NHBB bearings.

Dry Film Lubricant Basics

Dry film lubricants consist of MoS2 and small quantities of graphite or powdered metals. These lubricant compounds are bonded to the bearing race I.D. and often the ball O.D. and bore by either organic resins or inorganic binders (phenolic, sodium silicate, or other glass compositions). Hardening or curing is achieved by baking the applied lubricant at temperatures ranging from 300° to 1000°F depending upon the binding material.

The three most common dry film lubricants used with NHBB bearings are shown in the table below. NHBB can apply these dry film lubricants to all metal-to-metal spherical and rod end bearings. The advantages of a dry film lubricant include good tenacity, low coefficient of friction (0.05 to 0.25), and resistance to high bearing pressure (up to 90000 psi on hard substrates). Regarding wear characteristics, however, a dry film lubricant is not as predictable as a PTFE liner.

NHBB dry film lubricated bearings are used in aircraft and engine applications in which extreme temperature conditions exist (-300° to +1200°F).

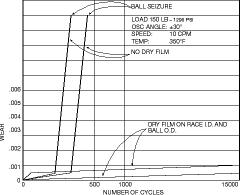

The graph on the right illustrates the difference in bearing life between dry filmed bearings and un-lubricated bearings.

Dry film lubricated vs. non-lubricated bearings.

Types of Dry Film Lubricants

| Type | Specification | Lubricant | Binder | Temperature Range | Use and Remarks |

|---|---|---|---|---|---|

| Solid film, heat cured, corrosion inhibiting | MIL-L-46010 Type I | MoS2 (no graphite or powdered metals), and corrosion inhibitors | Organic resins | -65° to +450°F | Good wear life. Used for most bearing applications other than extreme temperature situations. |

| Solid film, heat cured, corrosion inhibiting | MIL-L-46010 Type II | MoS2 (no graphite or powdered metals), and corrosion inhibitors | Organic resins | -90° to +400°F | Similar to MIL-L-46010, TYPE I except that it will provide added corrosion protection to substrate. Must have phosphate coating pretreatment for effective use on steel. |

| Solid film, extreme environment | MIL-PRF-81329 | MoS2 and other solid lubricants | Inorganic binders | -300° to +1200°F | To be used in extreme environments, i.e., vacuum, liquid oxygen, high temperatures. Wear life not as good as resin-bonded types. |

Dry Film Lubricants Used by NHBB

| Product | Specification | Temperature Range |

|---|---|---|

| E/M® 967 | -300° to +750°F | |

| Lubeco M-390 | MIL-L-46010, TY I | -65° to +500°F |

| Surf-Kote® LBO-1800-G | -65° to +1100°F | |

| Molykote® 106 | -321° to 450°F | |

| Everlube® 811 | MIL-PRF-81329 | -300° to +1200°F |

| Vitrolube 1220 | -400° to +700°F |

Trademarks

EVERLUBE® is a registered trademark of The Morgan Crucible Company PLC

E/M® is a registered trademark of the Morgan Crucible Company PLC

MOLYKOTE® is a registered trademark of Dow Corning Corporation

SURF-KOTE® is a registered trademark of Hohman Plating & Mfg. INC.