Engineering Reference

Rod End & Spherical Bearings

Bearing Retention

Bearing retention is an essential detail to consider when designing a bearing and for ensuring optimum bearing performance. It must be examined alongside other closely related design details, including bearing installation and staking methods, which we cover on separate pages.

Recommended Retention Methods

Bearing retention into a housing can be accomplished by any of the methods identified on this page, but several factors must be taken into account to determine the best approach. These considerations include the effect on bearing internal clearance and torque, the impact on the housing's residual stress, thermal expansion, added space and weight, retention capability, housing damage during bearing replacement, and the number of times a bearing can be replaced. The four retention methods listed in the table below are the most commonly used. Other methods do exist, such as adhesive bonding, snap rings, and threaded cover plates, but they should be used only as a last resort.

| Method | Effect on Bearing Internal Clearance | Effect on Housing Residual Stress | Added Space and Wt. | Retention Capability Requirements | Can Replacement Damage Housing? | Possible No. of Replacements |

|---|---|---|---|---|---|---|

| Threaded Bearing Retainer | None | None | None | Medium | No | No limit |

| Bolted Retainer | None | None | High | High | No | No limit |

| V-Groove Stake | None | None | None | Medium | No | No limit |

| Housing Stake: Continuous or Interrupted | High | High | None | Low | Yes | None |

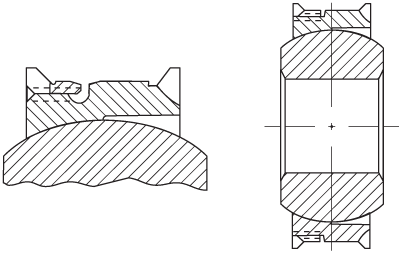

Threaded Retainer Retention

Threaded bearing retainers offer an excellent bearing retention method due to ease of bearing replacement, high axial thrust load capabilities, and ease of assembly in areas where accessibility to conventional staking would be difficult.

Threaded retainer retention.

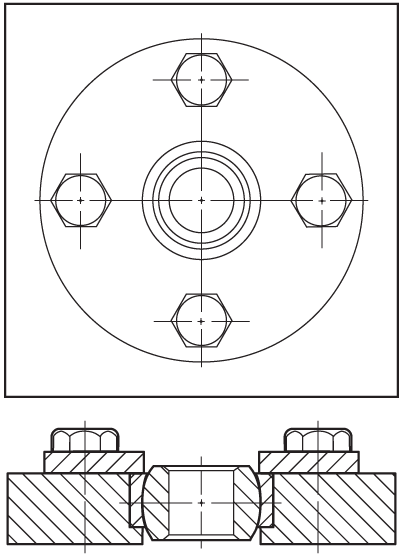

Bolted Plate Retention

For high retention capability and ease of bearing replacement, the bolted plate method is recommended. However, space requirements and weight will increase.

Bolted plate retention.

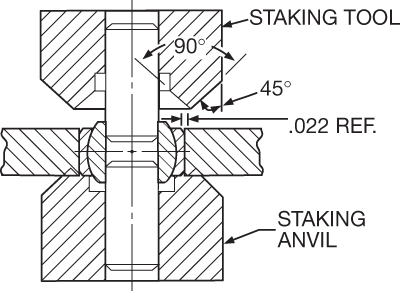

Housing Stake Retention

Housing stake retention has many shortcomings when compared to V-groove staking (below). The major consideration is race contraction, which adversely affects internal fit-up. Housing stake retention should be used only when there is insufficient space on the race face for a V-groove or the race material is not ductile. When mounting, the bearing and its housing are supported by an anvil while the staking tool is forced into one side of the housing near the edge of the bearing. This action displaces a small amount of the housing material over the race chamfer. The opposite side of the housing is then staked in the same manner.

Housing stake retention.

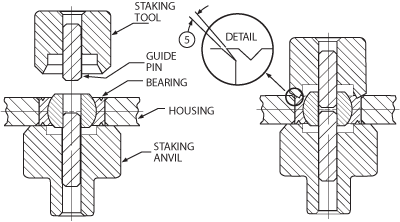

V-Groove Retention

V-groove retention is the most widely used and recommended. The bearing outer race has a small groove machined into each face, which leaves a lip on the race OD corners. With the use of staking tools, these lips are swaged (flared) over the chamfered edges of the housing.The prerequisites for good V-groove staking are proper size housing chamfers, staking tools that match the V-groove size, and the availability of a hydraulic or pneumatic press capable of applying the staking force. To use V-groove staking successfully, the following conditions must be met:

- Race hardness: Rc40 max.

- Sufficient space on the race face for machining a groove. See V-groove sizes here.

- V-groove size capable of carrying the axial load.

Visit the page about staking for more details about the staking procedure.

V-groove stake retention.