Engineering Reference

Miniature & Instrument Ball Bearings

Preload & Duplex Ball Bearings

Preload is defined as the initial axial load placed on a bearing or set of bearings during installation. Preloading facilitates precise control over the operating geometry of the bearing’s mating parts, a useful function in applications where axial and radial movement must be held within critical limits. Ball bearings are preloaded in order to:

Eliminate radial and axial looseness

Reduce operating noise

Improve positioning accuracy

Reduce repetitive runout

Reduce the possibility of damage from vibratory loading

Increase life and axial capacity

Increase stiffness

Preloading is accomplished either by using a spring preload or, as in duplex ball bearings, through a solid stack of parts. The three duplex bearing methods are described below, following the brief overview of spring preloading.

Spring Preloading

Spring preloading consists of a coil spring or a wavy washer that applies a force against the inner or outer ring of one of the bearings in the assembly. The spring force is normally applied against the non-rotating ring. Since a spring’s load is fairly consistent over a wide range of compressed length, the use of a spring for preloading eliminates the need for holding tight location tolerances on machined parts. For example, retaining rings can be used in the spindle assembly, thus saving the cost of a locating shoulder, shims or threaded members. Normally, a spring would not be used where the assembly must withstand reversing thrust loads.

Duplex Ball Bearings

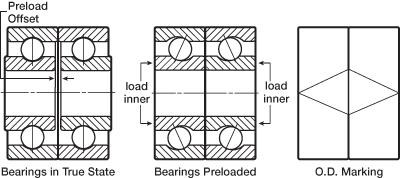

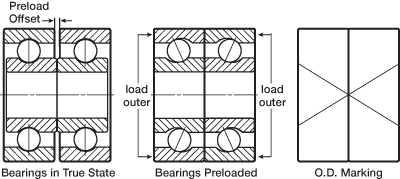

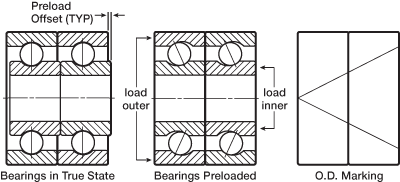

Duplex ball bearings are stacked pairs with built-in preloads. Duplex bearings are manufactured with the raceways of the inner and outer rings offset slightly. When the set of bearings is assembled, the thrust load required to press the adjacent faces of the rings together becomes the desired preload. Duplex ball bearings are used when precise location control is required. They also help satisfy the requirements of increased axial and radial stiffness and deflection control. The three methods of mounting preloaded duplex bearings are back-to-back (DB), face-to-face (DF) and tandem (DT):

Back-to-Back (DB)

When a back-to-back (DB) duplex pair is mounted, the outer rings abut and the inner rings are drawn together, providing maximum stiffness.

Back-to-Back (DB).

Face-to-Face (DF)

When face-to-face (DF) duplex pairs are mounted, the inner rings abut and the outer rings are drawn together, providing a higher radial and axial stiffness and accommodation of misalignment.

Face-to-Face (DF).

Tandem (DT)

With tandem (DT) pairs, both inner and outer rings abut and are capable of sharing a thrust load, providing increased thrust capacity.

Tandem (DT).