Engineering Reference

Precision Ball & Roller Bearings

(Medium to Large Diameter)

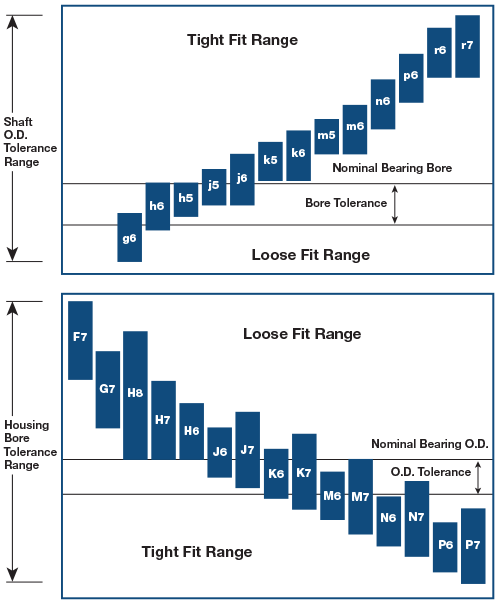

Shaft & Housing Fits

Establishing accurate shaft and housing fits is critical to achieving the best possible bearing performance. Fits that are too loose or too tight can create conditions that lead to premature bearing failure. Under certain conditions, overly loose fits can lead to corrosion of the shaft or bore, excessive wear, poor bearing rotation, and excessive vibration and noise. Exceedingly tight fits may cause large mounting and dismounting forces, unwanted preload, overheating, and a reduction in radial play.

Recommendations for Achieving Proper Fits

Shaft and housing fits are governed by the assembly’s specific operating requirements and conditions. The various factors to consider include the type and amount of load, operating temperature, running accuracy requirements, material composition and machining tolerances of mating components, and the size and type of bearing specified.

Generally speaking, the rotating ring of the bearing requires an interference fit with either the shaft or housing, and the nonrotating ring demands a slight loose fit with its mating component.

Thin cross section bearings, such as NHBB’s thin section and torque tube series, are inherently more sensitive to shaft and housing fits than metric ball and roller bearings. In most conditions a line-to-line-to-loose fit is more appropriate for thin cross sections. Heavier cross section bearings require tighter fits than light cross section bearings. In either case, extreme interference fits should only be used in conjunction with larger internal clearance in order to accommodate the subsequent loss of radial play.

The specific recommendations for shaft and housing fits for metric series radial ball and roller bearings are covered under ABMA Standard 7. The standards do not apply to inch series bearings. Consult HiTech’s Applications Engineering department ;for assistance.

The following tables provide fit recommendations for a variety of operating conditions and load magnitudes. Table I specifies the load classification. Tables II and III specify standard shaft and housing tolerance classifications. Tables IV and V identify the specific fit tolerances for NHBB’s metric series ball and cylindrical roller bearings up to 12” O.D. For help with verifying the correct fit for your application, or to request a complete bearing optimization, please consult NHBB’s Applications Engineering department.

Fit tolerances.

Determining Load Classification

To determine whether a load is either light, normal, or heavy, divide an application’s equivalent radial load (Pr) by the bearing’s dynamic radial load rating (Cr). Compare the results with Table I. See page 44 for a definition and method for calculating equivalent radial load.

Table I: Load Classification

| Light | Normal | Heavy | |

|---|---|---|---|

| Ball Bearings | 0.0 – 0.06 | 0.06 – 0.12 | 0.12 – 0.40 |

| Cylindrical Roller Bearings | 0.0 – 0.07 | 0.07 – 0.18 | 0.14 – 0.40 |

Table II: Classification for Shaft Tolerances

| Ball Bearings | Cylindrical Roller Bearings | |||||||

|---|---|---|---|---|---|---|---|---|

| Design and Operating Conditions | d | d | ||||||

| Rotational Conditions | Inner Ring Axial Displaceability | Radial Loading | Over | Incl. | Tolerance Classification | Over | Incl. | Tolerance Classification** |

| Inner Ring rotating in relation to load, or load direction is indeterminate. | Light | 0 0.71 | 0.71 All | h5 j6* | 0 1.57 5.51 12.60 19.70 | 1.57 5.51 12.60 19.70 All | j6* k6* m6* n6 p6 | |

| Normal | 0 0.71 | 0.71 All | j5 k5 | 0 1.57 3.94 5.51 12.60 19.70 | 1.57 3.94 5.51 12.60 19.70 All | k5 m5 m6 n6 p6 r6 | ||

| Heavy | 0.71 3.94 | 3.94 All | k5 m5 | 0 1.57 2.56 5.51 7.87 19.70 | 1.57 2.56 5.51 7.87 19.70 All | m5 m6 n6 p6 r6 r7 | ||

| Inner ring stationary in relation to load direction | Inner ring must be easily axially displaceable | Light, normal or heavy | All sizes | g6 | All sizes | g6 | ||

| Inner ring need not be easily axially displacable | Light, normal or heavy | All sizes | h6 | All sizes | h6 | |||

Dimensions are in inches.

For metric radial ball and roller bearings of tolerance classes ABEC 1 and RBEC 1.

**Values relate to solid steel shafts only. Tighter fits may be needed for hollow or nonferrous shafts.

*Select higher classification for greater accuracy (e.g., j5 for j6).

Copyright American Bearing Manufacturers Association, Inc. All rights reserved. Used with permission.

Table III: Classification for Housing Tolerances

| Design and Operating Conditions | ||||

|---|---|---|---|---|

| Rotational Conditions | Loading | Other Conditions | Axial Displaceability of Outer Ring | Tolerance Classification1 |

| Outer ring stationary in relation to load direction | Light, normal or heavy | Heat input through shaft | Easily displaceable | G7** |

| Housing split axially | H7* | |||

| Housing not split axially | H6* | |||

| Shock with temporary complete unloading | Transitional range2 | J6* | ||

| Load direction indeterminate | Light | |||

| Normal of heavy | Split not recommended | K6* | ||

| Heavy shock | M6* | |||

| Outer ring rotating in relation to load direction | Light | |||

| Normal of heavy | Not easily displaceable | N6* | ||

| Heavy | Thin wall housing not split | P6* | ||

For metric radial ball and roller bearings of tolerance classes ABEC 1 and RBEC 1.

*Substitute lower classifications where wider tolerances are allowed.

Please consult the factory.

**Use F7 if temperature differential between inner and outer ring of a large bearing is greater than 10 ˚C.

1Values relate to cast iron steel housings. Tighter fits may be needed for nonferrous alloys.

2The outer ring may either be tight or loose in the housing.

Copyright American Bearing Manufacturers Association, Inc. All rights reserved. Used with permission.

Table IV: Bore Fit Tolerances (g6 to k6)

| Tolerance Classifications | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| d | g6 | h6 | h5 | j5 | j6 | k5 | k6 | |||||||||

| Over | Incl. | Tolerance | shaft | Fit | shaft | Fit | shaft | Fit | shaft | Fit | shaft | Fit | shaft | Fit | shaft | Fit |

| 0.1181 | 0.2362 | 0 | -2 | 5L | 0 | 3L | 0 | 2L | 1 | 1L | 2 | 1L | 2 | 0 | ||

| -3 | -5 | 1T | -3 | 3T | -2 | 3T | -1 | 4T | -1 | 5T | 0 | 5T | ||||

| 0.2362 | 0.3937 | 0 | -2 | 6L | 0 | 4L | 0 | 2L | 2 | 1L | 3 | 1L | 3 | 0 | ||

| -3 | -6 | 1T | -4 | 3T | -2 | 3T | -1 | 5T | -1 | 6T | 0 | 6T | ||||

| 0.3937 | 0.7087 | 0 | -2 | 7L | 0 | 4L | 0 | 3L | 2 | 1L | 3 | 1L | 4 | 0 | ||

| -3 | -7 | 1T | -4 | 3T | -3 | 3T | -1 | 5T | -1 | 6T | 0 | 7T | ||||

| 0.7087 | 1.1811 | 0 | -3 | 8L | 0 | 5L | 2 | 2L | 4 | 2L | 4 | 1T | ||||

| -4 | -8 | 1T | -5 | 4T | -2 | 6T | -2 | 8T | 1 | 8T | ||||||

| 1.1811 | 1.9685 | 0 | -4 | 10L | 0 | 6L | 2 | 2L | 4 | 2L | 5 | 1T | 7 | 1T | ||

| -4.5 | -10 | 0.5T | -6 | 4.5T | -2 | 6.5T | -2 | 8.5T | 1 | 9.5T | 1 | 11.5T | ||||

| 1.9685 | 3.1496 | 0 | -4 | 11L | 0 | 7L | 2 | 3L | 5 | 3L | 6 | 1T | 8 | 1T | ||

| -6 | -11 | 2T | -7 | 6T | -3 | 8T | -3 | 11T | 1 | 12T | 1 | 14T | ||||

| 3.1496 | 4.7244 | 0 | -5 | 13L | 0 | 9L | 2 | 4L | 5 | 4L | 7 | 1T | 10 | 1T | ||

| -8 | -13 | 3T | -9 | 8T | -4 | 10T | -4 | 13T | 1 | 15T | 1 | 18T | ||||

| 4.7244 | 7.0866 | 0 | -6 | 15L | 0 | 10L | 3 | 4L | 6 | 4L | 8 | 1T | 11 | 1T | ||

| -10 | -15 | 4T | -10 | 10T | -4 | 13T | -4 | 16T | 1 | 18T | 1 | 21T | ||||

| 7.0866 | 7.8740 | 0 | -6 | 17L | 0 | 11L | 3 | 5L | 6 | 5L | 9 | 2T | ||||

| -12 | -17 | 6T | -11 | 12T | -5 | 15T | -5 | 18T | 2 | 21T | ||||||

| 7.8740 | 8.8583 | 0 | -6 | 17L | 0 | 11L | 3 | 5L | 6 | 5L | 9 | 2T | ||||

| -12 | -17 | 6T | -11 | 12T | -5 | 15T | -5 | 18T | 2 | 21T | ||||||

| 8.8583 | 9.8425 | 0 | -6 | 17L | 0 | 11L | 3 | 5L | 6 | 5L | 9 | 2T | ||||

| -12 | -17 | 6T | -11 | 12T | -5 | 15T | -5 | 18T | 2 | 21T | ||||||

| 9.8425 | 11.0236 | 0 | -7 | 19L | 0 | 13L | 3 | 6L | 6 | 6L | 11 | 2T | ||||

| -14 | -19 | 7T | -13 | 14T | -6 | 17T | -6 | 20T | 2 | 25T | ||||||

Dimensions are in inches.

Shaft deviations and resultant fits are in 0.0001 inches.

Copyright American Bearing Manufacturers Association, Inc. All rights reserved. Used with permission.

Table IV: Bore Fit Tolerances (m5 to r7)

| Tolerance Classifications | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| d | m5 | m6 | n6 | p6 | r6 | r7 | ||||||||

| Over | Incl. | Tolerance | shaft | Fit | shaft | Fit | shaft | Fit | shaft | Fit | shaft | Fit | shaft | Fit |

| 0.1181 | 0.2362 | 0 | 4 | 2T | ||||||||||

| -3 | 2 | 7T | ||||||||||||

| 0.2362 | 0.3937 | 0 | 5 | 2T | ||||||||||

| -3 | 2 | 8T | ||||||||||||

| 0.3937 | 0.7087 | 0 | 6 | 3T | ||||||||||

| -3 | 3 | 9T | ||||||||||||

| 0.7087 | 1.1811 | 0 | 7 | 3T | ||||||||||

| -4 | 3 | 11T | ||||||||||||

| 1.1811 | 1.9685 | 0 | 8 | 4T | 10 | 4T | ||||||||

| -4.5 | 4 | 12.5T | 4 | 14.5T | ||||||||||

| 1.9685 | 3.1496 | 0 | 9 | 4T | 12 | 4T | 15 | 8T | ||||||

| -6 | 4 | 15T | 4 | 18T | 8 | 21T | ||||||||

| 3.1496 | 4.7244 | 0 | 11 | 5T | 14 | 5T | 18 | 9T | 23 | 15T | ||||

| -8 | 5 | 19T | 5 | 22T | 9 | 26T | 15 | 31T | ||||||

| 4.7244 | 7.0866 | 0 | 13 | 6T | 16 | 6T | 20 | 11T | 27 | 17T | 35 | 26T | ||

| -10 | 6 | 23T | 6 | 26T | 11 | 30T | 17 | 37T | 26 | 45T | ||||

| 7.0866 | 7.8740 | 0 | 15 | 7T | 18 | 7T | 24 | 12T | 31 | 20T | 42 | 30T | ||

| -12 | 7 | 27T | 7 | 30T | 12 | 36T | 20 | 43T | 30 | 54T | ||||

| 7.8740 | 8.8583 | 0 | 15 | 7T | 18 | 7T | 24 | 12T | 31 | 20T | 43 | 31T | 50 | 31T |

| -12 | 7 | 27T | 7 | 30T | 12 | 36T | 20 | 43T | 31 | 55T | 31 | 62T | ||

| 8.8583 | 9.8425 | 0 | 15 | 7T | 18 | 7T | 24 | 12T | 31 | 20T | 44 | 33T | 51 | 33T |

| -12 | 7 | 27T | 7 | 30T | 12 | 36T | 20 | 43T | 33 | 56T | 33 | 63T | ||

| 9.8425 | 11.0236 | 0 | 17 | 8T | 20 | 8T | 26 | 13T | 35 | 22T | 50 | 37T | 57 | 37T |

| -14 | 8 | 31T | 8 | 34T | 13 | 40T | 22 | 49T | 37 | 64T | 37 | 71T | ||

Dimensions are in inches.

Shaft deviations and resultant fits are in 0.0001 inches.

Copyright American Bearing Manufacturers Association, Inc. All rights reserved. Used with permission.

Table V: Housing Fit Tolerances (F7 to K6)

| Tolerance Classifications | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| d | F7 | G7 | H8 | H7 | H6 | J6 | J7 | K6 | ||||||||||

| Over | Incl. | Tolerance | Housing | Fit | Housing | Fit | Housing | Fit | Housing | Fit | Housing | Fit | Housing | Fit | Housing | Fit | Housing | Fit |

| 0.3937 | 0.7087 | 0 | 6 | 16L | 2 | 12L | 0 | 14L | 0 | 10L | 0 | 7L | -2 | 5L | -3 | 7L | -4 | 4L |

| -3 | 13 | 6L | 9 | 2L | 11 | 0 | 7 | 0 | 4 | 0 | 2 | 2T | 4 | 3T | 1 | 4T | ||

| 0.7087 | 1.1811 | 0 | 8 | 19.5L | 3 | 14.5L | 0 | 16.5L | 0 | 11.5L | 0 | 8.5L | -2 | 6.5L | -4 | 8.5L | -4 | 4.5L |

| -3.5 | 16 | 8L | 11 | 3L | 13 | 0 | 8 | 0 | 5 | 0 | 3 | 2T | 5 | 4T | 1 | 4T | ||

| 1.1811 | 1.9685 | 0 | 10 | 24.5L | 4 | 17.5L | 0 | 19.5L | 0 | 14.5L | 0 | 10.5L | -2 | 8.5L | -4 | 10.5L | -5 | 5.5L |

| -4.5 | 20 | 10L | 13 | 4L | 15 | 0 | 10 | 0 | 6 | 0 | 4 | 2T | 6 | 4T | 1 | 5T | ||

| 1.9685 | 3.1496 | 0 | 12 | 29L | 4 | 21L | 0 | 23L | 0 | 17L | 0 | 12L | -2 | 10L | -5 | 12L | -6 | 7L |

| -5 | 24 | 12L | 16 | 4L | 18 | 0 | 12 | 0 | 7 | 0 | 5 | 2T | 7 | 5T | 2 | 6T | ||

| 3.1496 | 4.7244 | 0 | 14 | 34L | 5 | 25L | 0 | 27L | 0 | 20L | 0 | 15L | -2 | 12L | -5 | 15L | -7 | 8L |

| -6 | 18 | 14L | 19 | 5L | 21 | 0 | 14 | 0 | 9 | 0 | 6 | 2T | 9 | 5T | 2 | 7T | ||

| 4.7244 | 5.9055 | 0 | 17 | 40L | 6 | 28L | 0 | 32L | 0 | 23L | 0 | 17L | -3 | 14L | -6 | 17L | -8 | 9L |

| -7 | 33 | 17L | 21 | 6L | 25 | 0 | 16 | 0 | 10 | 0 | 7 | 3T | 10 | 6T | 2 | 8T | ||

| 5.9055 | 7.0866 | 0 | 17 | 43L | 6 | 31L | 0 | 35L | 0 | 26L | 0 | 20L | -3 | 17L | -6 | 20L | -8 | 12L |

| -10 | 33 | 17L | 21 | 6L | 25 | 0 | 16 | 0 | 10 | 0 | 7 | 3T | 10 | 6T | 2 | 8T | ||

| 7.0866 | 9.8425 | 0 | 20 | 50L | 6 | 36L | 0 | 40L | 0 | 30L | 0 | 23L | -3 | 21L | -6 | 24L | -9 | 14L |

| -12 | 38 | 20L | 24 | 6L | 28 | 0 | 18 | 0 | 11 | 0 | 9 | 3T | 12 | 6T | 2 | 9T | ||

| 9.8425 | 12.4016 | 0 | 22 | 57L | 7 | 41L | 0 | 46L | 0 | 34L | 0 | 27L | -3 | 24L | -6 | 28L | -11 | 16L |

| -14 | 43 | 22L | 27 | 7L | 32 | 0 | 20 | 0 | 13 | 0 | 10 | 3T | 14 | 6T | 2 | 11T | ||

Dimensions are in inches.

Housing deviations and resultant fits are in 0.0001 inches.

Copyright American Bearing Manufacturers Association, Inc. All rights reserved. Used with permission.

Table V: Housing Fit Tolerances* (K7 to P7)

| Tolerance Classifications | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| d | K7 | M6 | M7 | N6 | N7 | P6 | P7 | |||||||||

| Over | Incl. | Tolerance | Housing | Fit | Housing | Fit | Housing | Fit | Housing | Fit | Housing | Fit | Housing | Fit | Housing | Fit |

| 0.3937 | 0.7087 | 0 | -5 | 5L | -6 | 1L | -7 | 3L | -8 | 1T | -9 | 1L | -10 | 3T | -11 | 1T |

| -3 | 2 | 5T | -2 | 6T | 0 | 7T | -4 | 8T | -2 | 9T | -6 | 10T | -4 | 11T | ||

| 0.7087 | 1.1811 | 0 | -6 | 5.5L | -7 | 1.5L | -8 | 3.5L | -9 | 0.5T | -11 | 0.5L | -12 | 3.5T | -14 | 2.5T |

| -3.5 | 2 | 6T | -2 | 7T | 0 | 8T | -4 | 9T | -3 | 11T | -7 | 12T | -6 | 14T | ||

| 1.1811 | 1.9685 | 0 | -7 | 7.5L | -8 | 2.5L | -10 | 4.5L | -11 | 0.5T | -13 | 1.5L | -15 | 3.5T | -17 | 2.5T |

| -4.5 | 3 | 7T | -2 | 8T | 0 | 10T | -5 | 11T | -3 | 13T | -8 | 15T | -7 | 17T | ||

| 1.9685 | 3.1496 | 0 | -8 | 9L | -9 | 3L | -12 | 5L | -13 | 1T | -15 | 1L | -18 | 5T | -20 | 3T |

| -5 | 4 | 8T | -2 | 9T | 0 | 12T | -6 | 13T | -4 | 15T | -10 | 18T | -8 | 20T | ||

| 3.1496 | 4.7244 | 0 | -10 | 10L | -11 | 4L | -14 | 6L | -15 | 0 | -18 | 2L | -20 | 6T | -23 | 3T |

| -6 | 4 | 10T | -2 | 11T | 0 | 14T | -6 | 15T | -4 | 18T | -12 | 20T | -9 | 23T | ||

| 4.7244 | 5.9055 | 0 | -11 | 12L | -13 | 4L | -16 | 7L | -18 | 1T | -20 | 2L | -24 | 7T | -27 | 4T |

| -7 | 5 | 11T | -3 | 13T | 0 | 16T | -8 | 18T | -5 | 20T | -14 | 24T | -11 | 27T | ||

| 5.9055 | 7.0866 | 0 | -11 | 15L | -13 | 7L | -16 | 10L | -18 | 2L | -20 | 5L | -24 | 4T | -27 | 1T |

| -10 | 5 | 11T | -3 | 13T | 0 | 16T | -8 | 18T | -5 | 20T | -14 | 24T | -11 | 27T | ||

| 7.0866 | 9.8425 | 0 | -13 | 17L | -15 | 9L | -18 | 12L | -20 | 3L | -24 | 6L | -28 | 4T | -31 | 1T |

| -12 | 5 | 13T | -3 | 15T | 0 | 18T | -9 | 20T | -6 | 24T | -16 | 28T | -13 | 31T | ||

| 9.8425 | 12.4016 | 0 | -14 | 20L | -16 | 10L | -20 | 14L | -22 | 4L | -26 | 8L | -31 | 5T | -35 | 0 |

| -14 | 6 | 14T | -4 | 16T | 0 | 20T | -10 | 22T | -6 | 26T | -19 | 31T | -14 | 35T | ||

Dimensions are in inches.

Housing deviations and resultant fits are in 0.0001 inches.

*Copyright American Bearing Manufacturers Association, Inc. All rights reserved. Used with permission.