Engineering Reference

Precision Ball & Roller Bearings

(Medium to Large Diameter)

Preload & Duplex Bearings

Preload is defined as the initial axial load placed on a set of bearings during installation. Preloading facilitates precise control over the operating geometry of the bearing’s mating parts, a useful function in applications where axial and radial movement must remain within critical limits. Below we outline the specific functional attributes of preloading, describe methods of applying preload, and identify four types of duplex ball bearings.

Functional Attributes of Preload

Preloading facilitates precise control over the operating geometry of the bearing’s mating parts, a useful function in applications where axial and radial movement must be held within critical limits. The specific functional attributes of preloading include:

- Removal of the free axial and radial play for precise shaft positioning. With the removal of free play, the geometries of the bearings dictate the radial and axial run-outs;

- Establishment of a precise amount of axial and radial stiffness. The spring rates in the axial and radial directions are constant as long as the preload is maintained;

- Minimization of ball skidding. Properly designed preloading keeps the balls under load in high speed or rapid acceleration/deceleration operation;

- Allowance of load sharing between bearings. Increased axial capacities can be realized using tandem duplexes.

Methods

Bearings may be preloaded using one of the following approaches:

- Specify factory “built-in” preload sets. Since each set is checked for preload level as it is built, these duplex bearings provide the greatest control over preload. The clamping load can be applied either with a single nut tightened to a specific torque, or a clamping ring with multiple screws tightened to a prescribed torque.

- Use shims and/or spacers to provide the preload deflection offsets. The appropriate faces can then be clamped as above to provide the preload. This method can result in wide ranges of preload, as lengths vary with shims or spacers.

- Use compression springs (wave washers, Belleville washers, etc.) to apply the initial axial load to the set. Due to tolerance stack-ups, this method is not very precise. The spring’s placement (with its lower spring rate) is critical for preventing preload unloading due to external axial loads.

Duplex Bearing Configurations

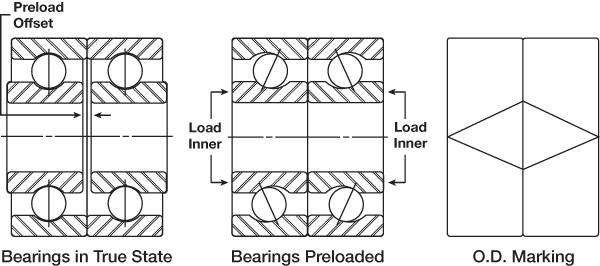

DB (back to back)

The outboard faces of this set’s inner rings are loaded, creating opposing contact angles that diverge to the bearing axis. Factory “built-in” offsets in the unloaded state provide the proper preload deflection when the inner races are clamped together. This configuration has higher moment stiffness than the DF configuration (under the same preload, DB and DF have identical radial and axial stiffness rates). Use DB when the shaft temperature is higher than the housing temperature, as this configuration minimizes preload build-up due to differential expansions, and reduces heat buildup in the bearings.

DB (back to back).

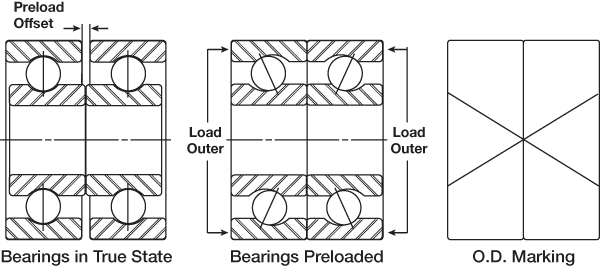

DF (face to face)

The outboard faces of this set’s outer rings are loaded, creating opposing contact angles that converge to the bearing axis inside the bearing envelope. Factory “built-in” offsets in the unloaded state provide the proper preload when the outer races are clamped together. This configuration has lower moment stiffness than DB, which allows for some misalignment. Use DF when the housing temperature is higher than the shaft temperature.

DF (face to face).

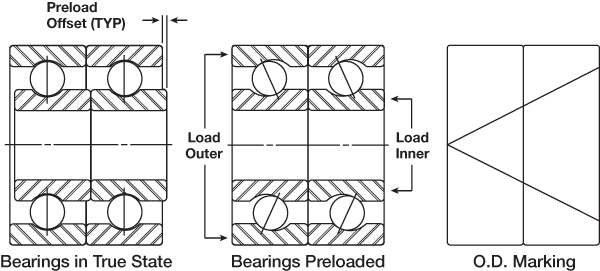

DT (tandem)

The contact angles of the bearings are oriented in the same direction, allowing for increased load sharing in the axial direction. DT has the same radial stiffness (with equal preload) as the DB or DF configurations, but its axial stiffness is twice that of either pair with the same preload. Factory “built-in” offsets in the unloaded state provide the proper preload when the outer race on one side and the inner race on the opposite side are loaded. To achieve a preloaded condition, DT requires an opposing bearing or bearing-set.

DT (tandem).

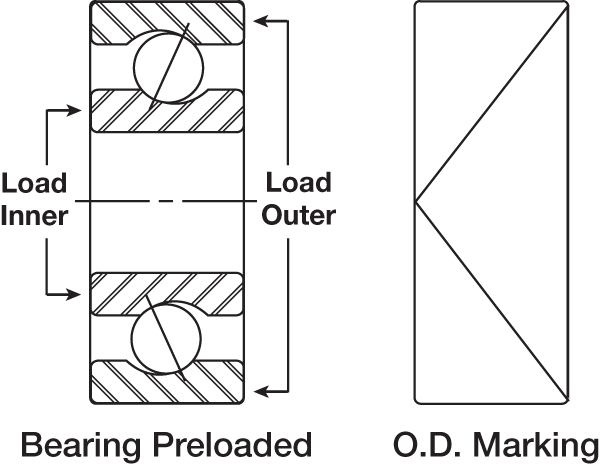

DU (universal)

The faces are flush on both sides with the factory “built-in” preload, so this version can be oriented in any configuration: DB, DF or DT.

DU (universal).