Engineering Reference

Precision Ball & Roller Bearings

(Medium to Large Diameter)

Ceramic Balls

Engineered specifically for bearings, silicon nitride (ceramic) balls possess highly controlled, consistent geometry and extremely smooth and consistent surface finish. The stiffness, light weight and inertness of silicon nitride balls offer significant bearing performance advantages, including higher operating speeds, lower heat generation, extended bearing life and expanded design possibilities for unique and demanding bearing applications. In addition, the dissimilar materials between the ceramic balls and the steel rings minimize cold welding and adhesive wear. Ceramic balls are particularly well suited for high speed applications and in situations where marginal lubrication is a possibility.

Typical Applications

- Micro turbines (power generation)

- Aircraft instrumentation

- Gas turbine engines

- Hot air valves

- Helicopter gear boxes

- Accessory gear boxes

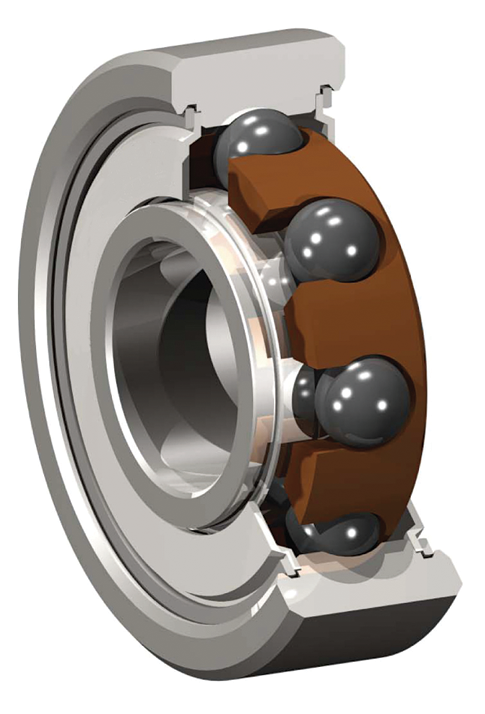

Cutaway rendering of a hybrid ceramic ball bearing.

Specifications

| Feature | Property |

|---|---|

| Material | Silicon nitride |

| Specifications | ASTM F2094 |

| Room Temperature Hardness | >1380 HV10 (>78 HRC) |

| Attributes | Extended life, lower torque, lighter weight, higher stiffnes |

Performane Benefits

| Properties | Improvement in Bearing Performance |

|---|---|

| Lower internal friction | Lower internal temperature Reduced cage and raceway wear |

| Lighter weight 58% lighter than steel | Lighter overall bearing weight Decreased centrifugal force Decreased gyroscopic movement |

| Higher stiffness & higher hardness | Reduced skidding Less friction Lower operating temperatures Less wear |

| Smoother surface 65% smoother than steel | Decreased lube degradation No cold welding/adhesive wear Less friction Lower operating temperature Less wear |

| Corrosion resistance | Durability in harsh environments Less wear Resists galling |

| Higher maximum temperature | Wider operating range |