Engineering Reference

Precision Ball & Roller Bearings

(Medium to Large Diameter)

Cages

NHBB utilizes numerous cage types consisting of different materials, manufacturing processes, and configurations to satisfy a diverse range of application requirements. A limited number of standard cage materials such as steel, bronze, phenolic, and nylon are sufficient to cover a broad spectrum of speeds and operating temperatures. In high speed, high temperature, and highly corrosive conditions, it may be necessary to specify more specialized materials such as silicon-iron bronze or steel with silver plating to improve performance and prolong bearing life. In high load conditions, the optimal solution may be a full ball complement-or cage-less-design. While the following information is a good starting point, our application engineers are ready to assist you in selecting the most appropriate cage configuration for your specific application.

Below we highlight the most common bearing cages for radial ball bearings; angular contact, gothic arch and fractured race ball bearings; and cylindrical roller bearings:

Radial Ball Bearings

| Style - pocket type | Piloting Surface | ‡ | Material (Fabrication Method) | Max. Speed [1000 dN*] | Max. Operating Temp. | Utility | Limitations | Typical Applications |

|---|---|---|---|---|---|---|---|---|

2-piece ribbon, spherical pocket (clinched) | Land | R | Steel (stamped) | 150 150 | 900 °F (482 °C) | Compact - seal or shield clearance, low starting torque, low cost | Low to moderate speeds only, high wear rate, mis-registration | General purpose, industrial |

| Ball | RD | |||||||

| 2-piece ribbon, spherical pocket (riveted) | Land | R4 | Steel (stamped) | 250 | 900 °F (482 °C) | Compact - seal or shield clearance, low starting torque, low cost | Moderate speed capability, high wear rate | Motors, generators |

| Ball | R6 | |||||||

2-piece ribbon, cylindrical pocket, skirted (riveted) | Inner Land | R5 | Phosphor bronze (stamped) | 1,000 | 400 °F (204 °C) | Higher speed/ strength capability, stable - tolerates higher acceleration | Higher cost, ground land (ring) surfaces, limited availability - consult factory | Transmission, power units |

| Outer Land | R7 | |||||||

| 2-piece, cylindrical pocket (riveted) | Inner Land | B1 | Leaded {80-10-10} Bronze (machined) | 1,000 | 500 °F (260 °C) | High speed/ strength capability | Moderate cost | Gearboxes |

| Outer Land | B2 | |||||||

| Inner Land | S1 | Steel - silver plate (machined) | 1,500 | 900 °F (482 °C) | Higher speed/ strength capability, corrosion resistant, lubricity | Higher cost - typically used with M50 rings and balls | Aircraft engine gear boxes | |

| Outer Land | S2 | |||||||

| Outer Land | M3 | Phenolic - linen base, aluminum side plates (machined) | 1,000 | 300 °F (149 °C) | High speed capability, can be impregnated with oil | Moderate cost, reduced clearance - typically used with open bearings | Starters, generators, high speed motors | |

| Crown, staggered cylindrical-spherical pocket | Ball | M8 | PEEK** (molded) | 1,000 | 500 °F (260 °C) | Light weight, high temperature/strength capability, abrasion resistant | Higher cost, limited availability - consult factory | High reliability, aerospace - power transmission |

| Crown, spherical pocket | Ball | M7 | PA*** - glass reinforced (molded) | 300 | 300 °F (149 °C) | Flexible - tolerates misalignment, low noise, abrasion/ impact resistant | Low cost/high volume, hygroscopic (3%), limited availability - consult factory | Industrial, electric motors, munitions |

| Crown, cylindrical pocket | Inner Land | KE | Phenolic - linen base (machined) | 600 | 300 °F (149 °C) | Lower mass-less centrifugal deflection, porous - can be impregnated with oil | Limited compatibility, hygroscopic, outgasses in a vacuum | Medical, machine tools, rotary joints, etc. |

| Outer Land | KF | |||||||

| Inner Land | M6 | PA*** - glass reinforced (molded) | 300 | 300 °F (149 °C) | Flexible - tolerates misalignment, low noise, abrasion/ impact resistant | Low cost/high volume, hygroscopic (3%), limited availability - consult factory | Industrial, electric motors, munitions |

Please note: Additional cage designs and materials are available. Consult the factory for assistance.

† See page 7 of our Roller and Ball Bearings Design Guide ;for alphanumeric part number code.

* dN = bore (in millimeters) x rpm.

** PEEK = Polyetheretherketone is a high-melt-temperature thermoplastic.

*** PA = Polyamide (a.k.a. Nylon or Nylon 6/6) is a high-melt-temperature thermoplastic.

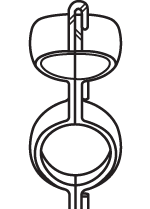

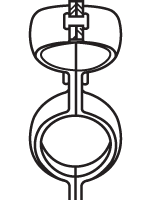

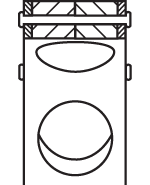

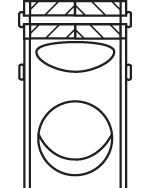

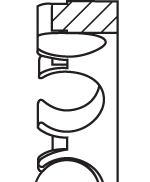

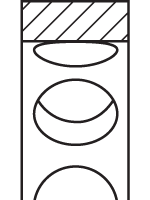

Drawings of Cages for Radial Ball Bearings

R, RD

R4, R6

R5, R7

B1, B2

S1, S2

M3

M8

M7

KE, KF

M6

Angular Contact, Gothic Arch, and Fractured Race Ball Bearings

| Style - pocket type | Piloting Surface | ‡ | Material (Fabrication Method) | Max. Speed [1000 dN*] | Max. Operating Temp. | Utility | Limitations | Typical Applications |

|---|---|---|---|---|---|---|---|---|

| 1-piece, cylindrical pocket | Land | ME | PEEK** (molded) | 1,000 | 500 °F (260 °C) | Light weight, high temperature/strength capability, tough, abrasion resistant | High cost, limited availability - consult factory | High reliability, aerospace - power transmission |

| Inner Land | KM | Phenolic - linen base (machined) | 1,500 | 300 °F (149 °C) | Quiet running, porous - can be impregnated with oil | Limited compatibility, hygroscopic, outgasses in a vacuum | Spindles, high speed motors, robotic joints | |

| Outer Land | KV | |||||||

| Land | MN | PA*** - glass filled (molded) | 750 | 300 °F (149 °C) | Quiet running, abrasion/impact resistant | Low cost/high volume, hygroscopic (3%), limited availability - consult factory | Motors, spindles, general purpose | |

| MX | Bronze**** (machined) | 1,500 | 500 °F (260 °C) | Thin cross section, higher ball groove shoulders, high speed/ strength capability | High cost | Power transmission, aircraft accessories | ||

| M2 | Steel - silver plate (machined) | 3,000 | 900 °F (482 °C) | Higher speed/ strength capability, corrosion resistant, lubricity | Higher cost | Aircraft accessories, high speed transmission | ||

| 1-piece, cylindrical pocket, with ball retention Typical - retention feature located opposite piloting surface | Inner Land | MP | Leaded (80-10-10) bronze (machined) | 1,000 | 350 °F (177 °C) | Moderate speed/strength capability | Moderate cost | Pumps, actuators, accessory gear boxes |

| Outer Land | MQ | |||||||

| Inner Land | B5 | Silicon-iron bronze (machined) | 2,000 | 500 °F (260 °C) | High speed/ strength capability | Higher cost | Gearboxes | |

| Outer Land | B6 | Silicon-iron bronze (machined) | ||||||

| Inner Land | S3 | Steel - silver plate (machined) | 3,000 | 900 °F (482 °C) | Higher speed/ strength capability, corrosion resistant, lubricity | Higher cost | High reliability mainshaft bearings, gea | |

| Outer Land | S4 | Steel - silver plate (machined) | ||||||

| Outer Land | KS | Phenolic - linen base (machined) | 1,500 | 300 °F (149 °C) | Quiet running, porous - can be impregnated with oil | Limited compatibility, hygroscopic, outgasses in a vacuum | Motors, spindles |

Please note: Additional cage designs and materials are available. Consult the factory for assistance.

† See page 7 of our Roller and Ball Bearings Design Guide ;for alphanumeric part number code.

* dN = bore (in millimeters) x rpm.

** PEEK = Polyetheretherketone is a high-melt-temperature thermoplastic.

*** PA = Polyamide (a.k.a. Nylon or Nylon 6/6) is a high-melt-temperature thermoplastic.

**** Types other than 80-10-10 (leaded bronze) are assigned a special design (SD) number. See Ball Bearing Part Numbering System on page 7 of our Roller and Ball Bearings Design Guide.

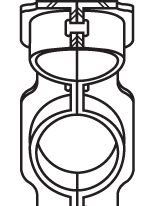

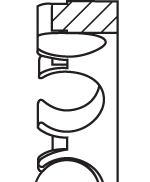

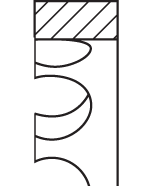

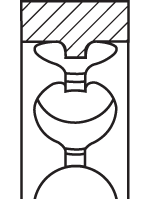

Drawings of Cages for Angular Contact, Gothic Arch and Fractured Race Ball Bearings

ME, KV, KM, MN, MX, M2

MP, MQ, B5, B6, S3, S4, KS

Cylindrical Roller Bearings

| Style - Pocket Type | Piloting Surface | ‡ | Material (Fabrication Method) | Max. Speed-dN* | Max. Operating Temp. | Utility | Limitations | Typical Applications |

|---|---|---|---|---|---|---|---|---|

| 1-piece, rectangular pocket, with roller retention Typical - retention feature located opposite piloting surface | Land | S | Steel - silver plate (machined) | 3,000 | 900 °F (482 °C) | Higher speed/ strength capability, corrosion resistant, lubricity | High cost | Mainshafts, gearboxes |

| B | Leaded {80-10-10} bronze (machined) | 1,000 | 350 °F (177 °C) | Moderate strength/ speed capability | Moderate cost | Pumps and Accessories | ||

| B | Silicon-iron bronze (machined) | 1,500 | 500 °F (260 °C) | High speed/ strength capability | Moderate cost | Gearboxes | ||

| P | PEEK** (molded) | 1,000 | 500 °F (260 °C) | Light weight, high temperature/strength capability, tough, abrasion resistant | High cost, limited availability - consult factory | High reliability, aerospace - power transmission | ||

| 1-piece, rectangular pocket, with roller retention Typical - retention feature located opposite piloting surface | Land | S | Steel - silver plate (machined) | 3,000 | 900 °F (482 °C) | Higher speed/ strength capability, corrosion resistant, lubricity | High cost | Mainshafts, gearboxes |

| B | Leaded {80-10-10} bronze (machined) | 1,000 | 350 °F (177 °C) | Moderate strength/ speed capability | Moderate cost | Pumps and Accessories | ||

| B | Silicon-iron bronze (machined) | 1,500 | 500 °F (260 °C) | High speed/ strength capability | Moderate cost | Gearboxes | ||

| P | PEEK** (molded) | 1,000 | 500 °F (260 °C) | Light weight, high temperature/strength capability, tough, abrasion resistant | High cost, limited availability - consult factory | High reliability, aerospace - power transmission |

† Typical nomenclature that corresponds to material type only. Other distinguishing features are defined according to a unique dash number. See Roller Bearing Part Numbering System on page 6 of our Roller and Ball Bearings Design Guide.

S = Steel with silver plate

B = Bronze

P = Plastic

* dN = bore (in millimeters) x rpm.

** PEEK = Polyetheretherketone, a high-melt-temperature thermoplastic.

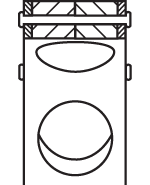

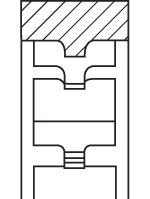

Drawings of Cages for Cylindrical Roller Bearings

S, B, P

S, B, P variation